AR Photopolymer Advance Resin

Description

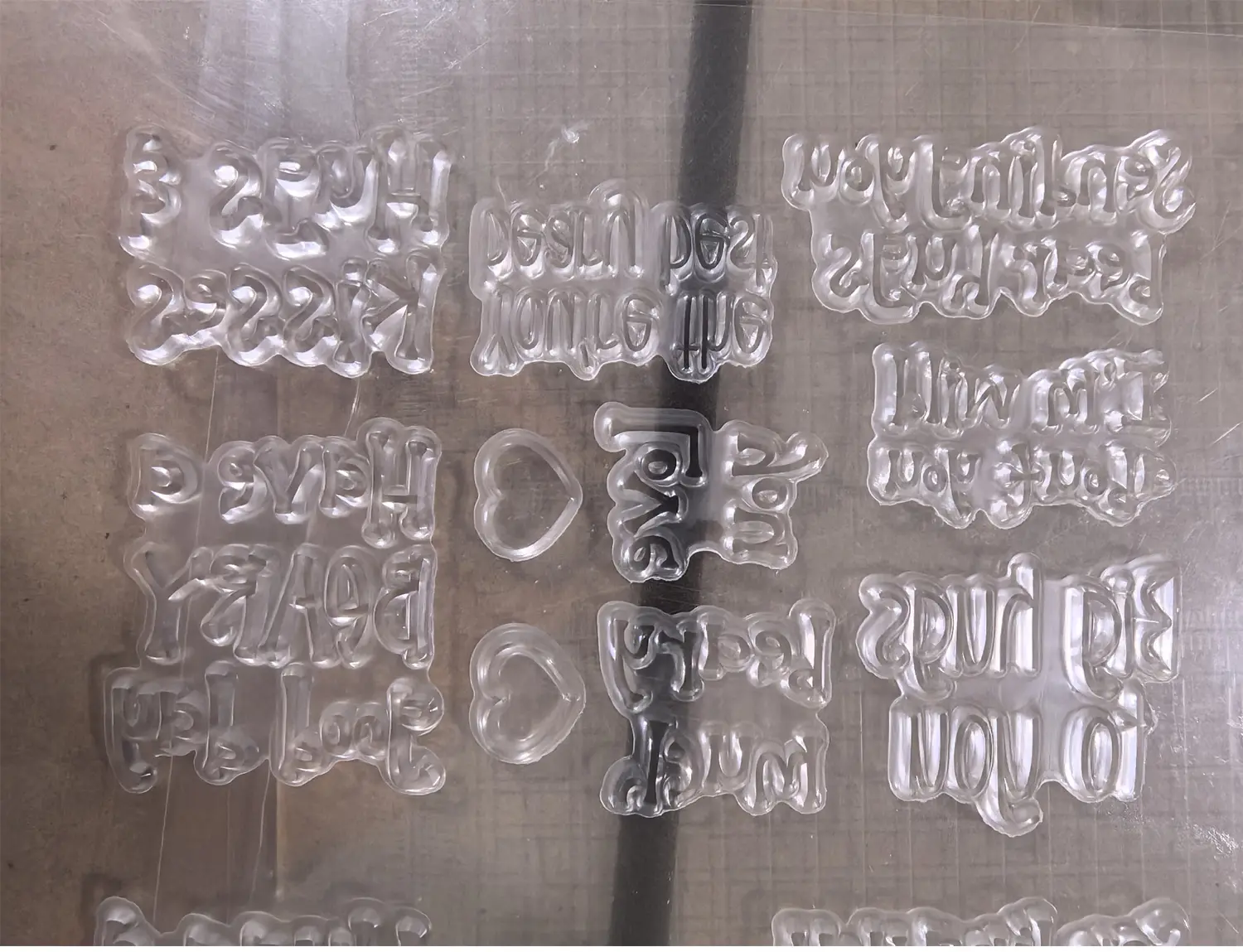

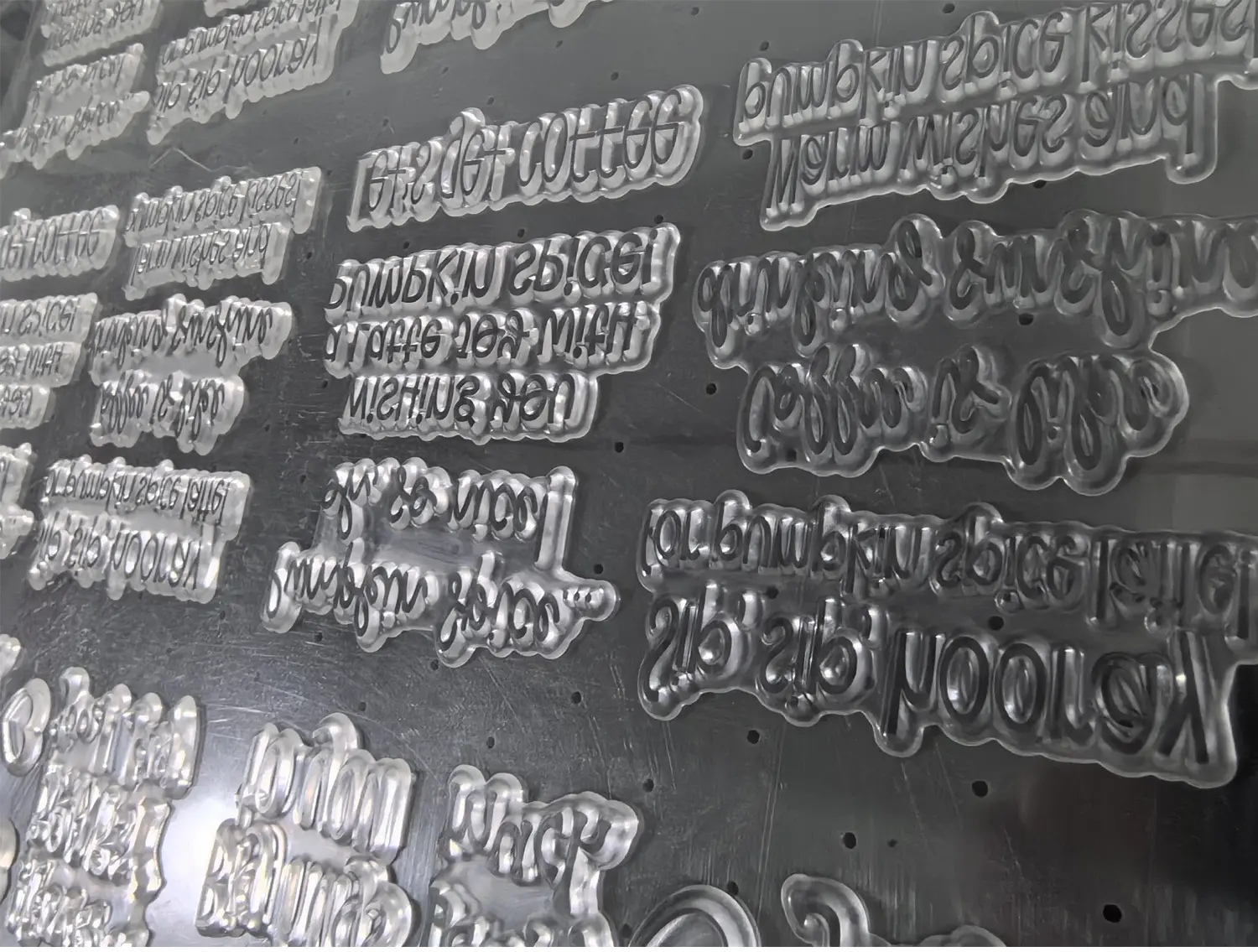

AR Photopolymer Advance Resin is a high-quality photopolymer resin specially designed for rubber stamp plate making. This advance resin polymer works under controlled UV light radiation and changes from liquid into a flexible rubber plate after exposure.

The resin forms strong and accurate plates with excellent shape stability. After UV curing, it becomes a durable elastomer that delivers clear and sharp stamp impressions. It supports both water-based ink and oil-based ink, making it suitable for many stamping applications.

This photopolymer resin is easy to use, environmentally friendly, and offers reliable results when stored away from direct sunlight.

Features

- High-quality photopolymer resin for rubber stamp plates

- Excellent font clarity for sharp and clean impressions

- Water-washable resin, no chemical solvents required

- Strong dimension stability for accurate plate formation

- Suitable for large-size rubber stamp plates

- Resistant to moisture, abrasion, oxidation, and ozone

- Flexible and durable rubber-like finish after UV exposure

- Long shelf life when not exposed to direct sunlight

- Environmentally friendly advance resin polymer

- Compatible with water-based and oil-based inks

- Available Variants:

- Clear Color – Photosensitive UV curable adhesive, 1 Kg

- Orange Color – Photosensitive UV curable adhesive, 1 Kg

Specifications

| Product Name | AR Photopolymer Advance Resin |

| Product Type | Photopolymer resin for UV rubber stamp plate making |

| Material | Advance resin polymer (liquid photopolymer) |

| Application | Rubber stamp plate making under controlled UV light exposure |

| UV Curing | Cures under ultraviolet light and converts into flexible rubber plate |

| Ink Compatibility | Compatible with both water-based and oil-based inks |

| Wash Type | Water washable photopolymer resin |

| Font Clarity | High font clarity for sharp and clean stamp impressions |

| Dimension Stability | Excellent dimension stability for accurate plate size |

| Plate Size Support | Suitable for small and large dimension rubber stamp plates |

| Resistance Properties | Moisture resistance, abrasion resistance, oxidation resistance, and ozone resistance |

| Shelf Life | Long life when stored away from direct sunlight |

| Environmental Safety | Environmentally friendly photopolymer resin |

| Key Features |

– High-quality photopolymer resin for rubber stamps – Water washable, easy to use – Produces flexible and durable rubber plates – Sharp font clarity and smooth impressions – Suitable for large size stamp plates – Long-lasting advance resin polymer |

| Available Variants |

Photosensitive UV curable adhesive – Clear Colour (1 Kg) Photosensitive UV curable adhesive – Orange Colour (1 Kg) |

| Ideal For | Rubber stamp manufacturers, printing units, packaging industry, offices, and stamp making professionals |

| Usage Instructions |

– Pour resin into plate mold – Expose under controlled UV light – Wash plate with water after curing – Dry and post-cure before use – Store resin away from direct sunlight |

| Extra Value | Reliable photopolymer resin with long life, strong resistance, and consistent stamp quality |

| What’s Included |

|

| Packaging Volume |

1 Kg Pack (Clear Colour): Inner – 1 Packs / Shipper – 48 Packs 1 Kg Pack (Orange Colour): Inner – 1 Packs / Shipper – 48 Packs Bulk Supply: Suitable for rubber stamp manufacturers, printing units, packaging industry, offices, and stationery distributors |

Usage

AR Photopolymer Advance Resin is mainly used for making rubber stamp plates using UV exposure.

- Pour the liquid photopolymer resin into the mold.

- Expose it to controlled UV light.

- The resin cures and turns into a flexible elastomer plate.

- Wash the plate with water to remove uncured resin.

- Dry and post-cure the plate before use.

The finished rubber stamp plate works smoothly with both water-based and oil-based inks and is ideal for stamp manufacturers, printing units, and office use.